24 X 7 CUSTOMER CARE: +91 9909 923 204

WATER SYSTEMS

Since the last 30 years, Pharmalab has been a leading supplier of plants producing water for injection, meeting international standards, including USP, IP, BP and JP.

STERILIZER

Our sterilizers have been engineered to meet the stringent manufacturing standards of cGMP, MHRA, USFDA. Our manufacturing is in accordance with GAMP & ISO 9001 guidelines.

FILTRATION SYSTEM

Through our strength of understanding the process know-how we provide filtration solutions that benefit the user. Our experience in wide range of applications, with varying product characteristics and operating conditions help serve our customers better each time to achieve cent percent customer satisfaction.

3000+ Clients

Since 1962

HEALTHCARE

Our range of products for the Central Sterile Services Department is widely used for sterilization and other actions on medical devices, equipment and consumables.

PACKAGING

Ensuring undiluted focus on liquid packaging, we specialize in manufacturing packaging equipment for a wide range of liquids, powders, and viscous products.

BARRIER ISOLATORS

Our partner, SKAN AG, headquartered in Switzerland is a global market and technological leader for isolators, cleanroom devices, and decontamination processes for the aseptic production of biopharmaceutical substances.

PROCESS EQUIPMENT

Our range of process equipment is built by our engineers through their vast technical experience and continuous research. These qualify the cGMP guidelines and comply to the norms set by USFDA, USPE, GAMP piping and ACME.

WE ARE TRUSTED BY

WORLD'S LEADING COMPANIES

Reliable & High-Quality

Equipments & Machinery

-

SMART STILL

-

VENTILATOR STERILIZER – AIR AND STEAM MIXTURE

-

WIRELESSGT 2– GLOVE INTEGRITY TESTING DEVICE

-

ALPHA PORT FLUSHFLOOR

-

ROTARY VACUUM DRUM FILTER

Smart Still

Pharmalab has been a leading supplier of Water for Injection Plant and Pure Steam Generators for more than three decades. With an aim of providing better solution to its customers, Pharmalab has designed a Smart Still, combination of WFI generation plant and Pure Steam generator,to produce WFI and Pure Steam from a single unit. It is designed to produce WFI & Pure Steam either simultaneously or independently. Smart Still is designed to meet the stringent standards set by major pharmacopoeias like USP, IP, BP, and JP. The still is manufactured as per FDA – current Good Manufacturing Practices (cGMP) and in accordance to ASME requirement. The WFI and Pure Steam is produced on the basic principle of Distillation by Thin Film Evaporation.

Ventilator Sterilizer – Air And Steam Mixture

Air & steam mixture (Ventilator) terminal sterilizer is an efficient method for terminal sterilization of large volume parental in plastic pouches, solutions in open or semi closed containers, glass containers, vials or ampoules, contact lenses in blisters, pre-filled syringes etc. The key feature of this method is that the product is completely dry after sterilization. The load is introduced on appropriate carriages and trays into the chamber, followed by allowing steam to enter the chamber through a perforated conduit located at the top.

WirelessGT 2– Glove Integrity Testing Device

WirelessGT is the most advanced and fully automated glove leak testing system, according to cGAMP, with pressure decay measurement for isolators and RABS in the Pharmaceutical industry. Operation is simple and without tubes and wires. All the functions necessary for performing a reliable glove test are integrated in the battery-powered test cover. The test monitors the pressure loss of the glove/sleeve assembly over a defined time. More than 1000 SKAN glove test covers have already been sold.

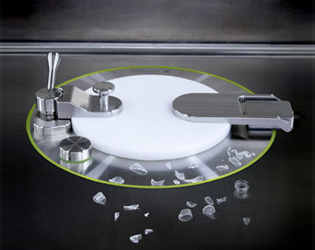

Alpha Port Flushfloor

The castus alpha Port serves as a transfer port for the contamination-free loading or unloading of components in or out of the isolator. The flush-mounted installation e.g. facilitates the removal of broken glass, as there is no protruding edge. This makes it easier to clean the isolator. The alpha Port Flushfloor is individually adapted to every workstation so that your tasks can be carried out optimally.

Rotary Vacuum Drum Filter

The sophisticated design of “Pharmalab Rotary Vacuum Drum Filter (RVDF)”is user friendly as it reduces manual operation by providing automated slurry level maintenance in the trough, automated transfer of filtrate from vacuum tank and automatic cake discharge arrangement. The trough is provided with tilt arrangement to control the immersion, reduce dead time between the cake discharge and drum immersion for new cycle to start and increase drying time.

What Our Clients Say?

-

We are satisfied with the quality and performance of the machines supplied by Phamalab. The installation, commissioning IQ, OQ and validation was successfully completed by them for our vaccine manufacturing facility.

Dr. Manish Bhatt

VP Engineering-

We would like to appreciate the efficient and good quality services provided by Pharmalab. The satisfactory completion of the project was possible due to the steady and dedicated hard work of the entire team. We consider your services as an added asset to our company and wish to continue our association in the long run.

Lheela Theerakam

LBS Laboratories Pvt LtdOur Upcoming Events

Stay tuned with Industry updates

| Thank you for Signing Up |

Interesting Reads

26May

Revolutionizing WFI Generation with VAPOSTIL™

- by pharmalab,

- 0 Comments

Water for Injection (WFI) is a critical requiremen...

31Jan

Drink Technology ’24 – Expanding horizons beyond the Pharmaceuticals

- by pharmalab,

- 0 Comments

Pharmalab Group Showcases Excellence at Drink Tech...

31Jan

Unveiling Innovations at PMEC 2024

- by pharmalab,

- 0 Comments

We are thrilled to share the highlights of our par...