NEWSLETTER

ISSUE

Issue Jan to Mar, 2023 Volume 21

ALLIANCE UPDATES

Our technical partner, castus® is a specialist for rapid transfer systems (RTP). Their built system allows contamination–free loading and unloading of components in and out of the isolator with focus on the optimal protection of the operator and the product. All products are developed with hygienic design principles in mind and fulfil the high-quality standards of the pharmaceutical industry.

In March 2021, castus® joined forces with the stopper processing specialist, HANAG, based in Basel. With more than 60 years of experience, HANAG Steriltechnik AG is one of the most important Swiss manufacturers in plant and system construction. The group’s focus is on sterile applications, with an established customer base for stopper and cap treatment systems.

castus® Component Processing System (CPS)

Clean, sterile, and dry stoppers and caps are one of the most critical requirements for primary packaging in pharmaceutical manufacturing. To ensure these requirements, the stoppers and caps are treated using various steps – Washing, Siliconizing, Sterilization, Drying and Cooling. Typically, the pharmaceutical companies either use already treated (by third party) stoppers or carry out the treatment in-house.

For in-house treatment, a conventional method of separate washing followed by siliconizing and sterilizing in bung processing sterilizer is followed. However, treating these stoppers in different systems always poses risk of contamination and integrity. To overcome these challenges, an advanced system such as CPS – Component Processing System is introduced that ensures addressing the critical requirements while offering sophisticated operation.

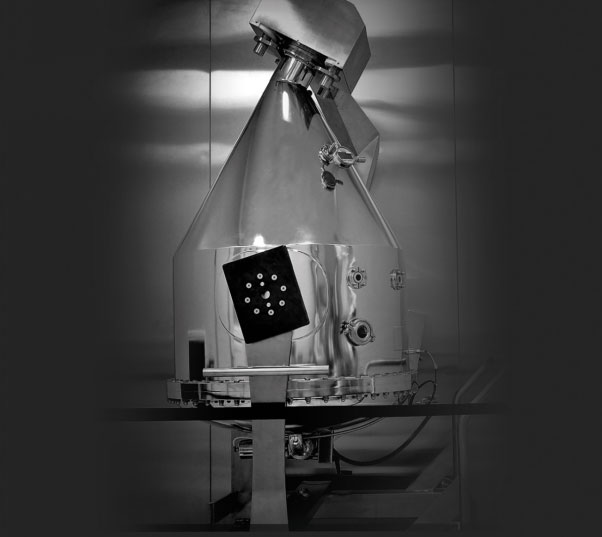

What is CPS?

CPS – Component Processing System provides clean, sterilized, and dried stoppers and caps for primary packaging in pharmaceutical processing. CPS includes the required treatment steps – Washing, Siliconizing, Sterilization, Drying and Cooling.

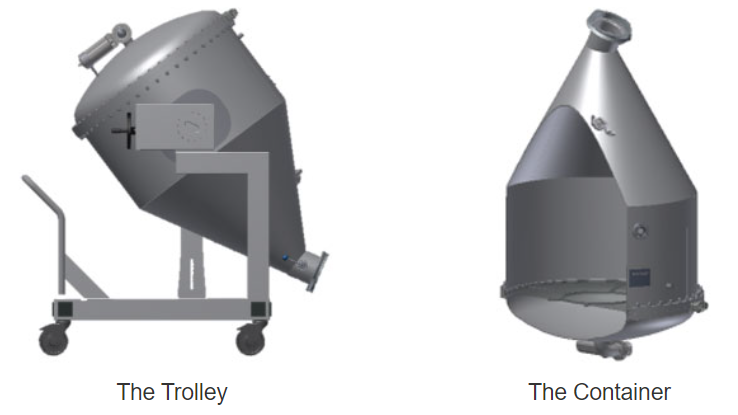

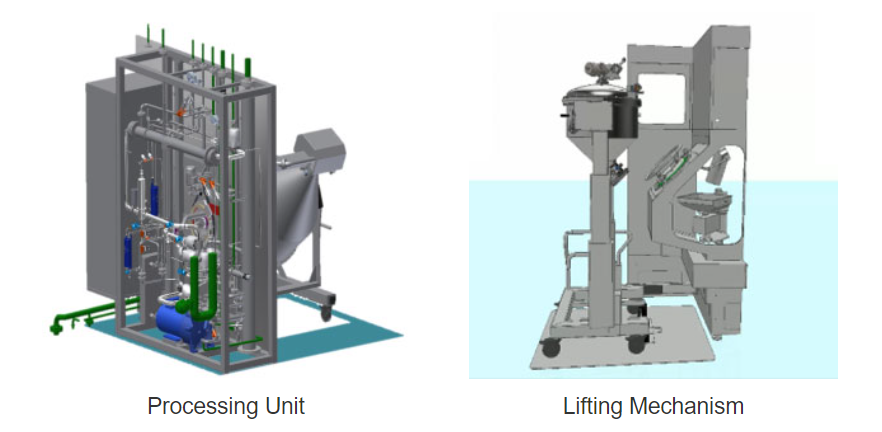

The CPS consists of four main components:

- Container with lifting trolley

- Loading mechanism

- Treatment station

- Discharge unit

What are the advantages of CPS?

- Microbial reduction

- Reduction of particles to a minimum

- Smooth treatment

- Homogenous silicone distribution

- High drying efficiency

- High process reliability

- Reduces manual intervention

- Reduces operation cost compared to ready-to-use (RTU) stoppers

How is the processing of the stoppers and caps done?

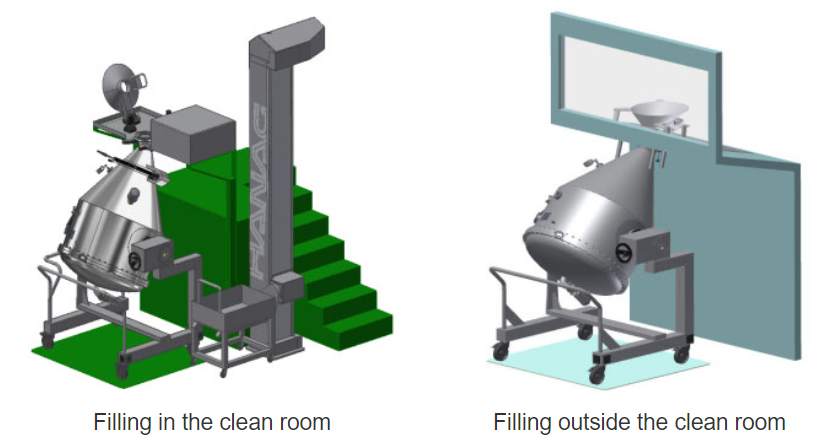

- Filling of processing container

- Treatment of stoppers/caps

- Discharge of container

- Inspection of container

FILLING OF PROCESSING CONTAINER

Subscribe to our Newsletter

Stay tuned with Industry updates

| Thank you for Signing Up |