NEWSLETTER

ISSUE

Apr to Jun, 2022 Volume 18

BRAIN WAVE

ATF Sterilization Cycle

One of the unique systems commonly used in the biopharmaceutical facility is the ATF system. Alternating Tangential Flow Filtration (ATF) technology is a filtration method used in various industrial applications to purify the desired component out of the sample. ATF is used as a preferred cell retention system in the perfusion process of cell culture, proteins and antibodies. ATF is commonly used in the production of Monoclonal antibodies, Recombinant proteins, Vaccines and Viral vectors. The alternating flow of the retentate cleans the filter, enabling it to be used for more prolonged and continuous processing.

One of the unique systems commonly used in the biopharmaceutical facility is the ATF system. Alternating Tangential Flow Filtration (ATF) technology is a filtration method used in various industrial applications to purify the desired component out of the sample. ATF is used as a preferred cell retention system in the perfusion process of cell culture, proteins and antibodies. ATF is commonly used in the production of Monoclonal antibodies, Recombinant proteins, Vaccines and Viral vectors. The alternating flow of the retentate cleans the filter, enabling it to be used for more prolonged and continuous processing.

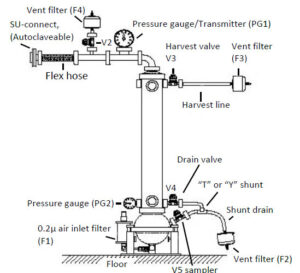

The ATF system comprises of stainless-steel housing to enclose the hollow fiber cartridge. The hollow fibers are extremely fine, offering Micro-Filtration (0.1 to 0.65 µm) and Ultra-filtration (10-750 KDa). However, these fibers are heat and pressure-sensitive and can easily get damaged with instant pressure and temperature changes. Therefore, standard sterilization cycles such as liquid, gravity or HPHV may not be suitable for ATF sterilization. An autoclave requires a more complex sterilization cycle to ensure both device sterility and avoid thermal stress that may damage the hollow fiber cartridge. In addition, this cycle calls for precise control of critical parameters.

The ATF system comprises of stainless-steel housing to enclose the hollow fiber cartridge. The hollow fibers are extremely fine, offering Micro-Filtration (0.1 to 0.65 µm) and Ultra-filtration (10-750 KDa). However, these fibers are heat and pressure-sensitive and can easily get damaged with instant pressure and temperature changes. Therefore, standard sterilization cycles such as liquid, gravity or HPHV may not be suitable for ATF sterilization. An autoclave requires a more complex sterilization cycle to ensure both device sterility and avoid thermal stress that may damage the hollow fiber cartridge. In addition, this cycle calls for precise control of critical parameters.

A recommended cycle sequence by the ATF system manufacturer strongly advises adherence to the cycle parameters to achieve desired results and maintain cartridge integrity. The suggested procedure includes three pre-vacuum pulses, which provide proper chamber evacuation for a faster and more consistent ramp to the required temperature. The pre-requisite for ATF sterilization consists of a thoroughly wetted filter, assembly installed with appropriate vent filters, all valves open, loose clamps, and ATF placed vertically or at an angle but not in the horizontal position.

The sterilization cycle sequence will be as follows:

The sterilization cycle sequence will be as follows:

- Pre-heating ATF device for 60 to 90 minutes using sterilizer jacket heat only, i.e. no direct steam. The cartridge should reach ~60°C through convective heating in the chamber.

- Followed by the purge cycle for 5 minutes and the pressure not exceeding six psig.

- Start the vacuum pulse, using an exhaust rate of -1 psig/min up to -6 psig and hold vacuum for 1 minute, then apply steam pressure to 6 psig and hold for 20 minutes.

- Repeat the above vacuum/pressure pulse three times.

- After the fourth vacuum pulse, gradually apply steam pressure to reach the sterilization setting of 15 psig / 121 – 123°C by controlling the temperature rise to 1°C/minute.

- The sterilization phase continues for 55 to 60 minutes.

- Post sterilization, the cooling phase should initiate with a slow cooling rate to avoid thermal stress on the filter cartridge and partial water drying in the membrane pores. The temperature should reduce at a rate of 0.5 to 1°C/minute to about 0.1 psig or 100°C. Optionally, cooling can continue until the door open temperature is reached, i.e. 40 to 50°C.

- Upon attaining door open temperature, open the chamber door and, tighten all connections, inspect for any damages or other irregularities. Close valves only after the system reach ambient temperature.

| Stage | Time (min) | Set Point | Chamber Temp(°C) appx value | Chamber Pressure (psig) appx value | Remarks |

| Pre-heat | 60-90 | 60°C | 59 | 0.1 | Convective heat gently pre-heat the system |

| Purge | 5 | 6 | 110 | 6 | Steam purge removes chamber air |

| Vacuum 1 | 12 | -1.0 psig/min | 85 | -6 psig | Remove air/steam mixture at a controlled rate |

| Vacuum Hold | 1 | <-6 psig | 81 | -6 psig | |

| Purge | <1 | 6 psig | 110 | 6 | Steam to a low pressure setting |

| Hold | 20 | 6 psig | 110 | 6 | Hold time allows the temperature to equilibrate within the assembly |

| Vacuum 2 | 12 | -1.0 psig/min | 85 | -6 psig | Repeat pulses to remove air and uniformly heats the assembly |

| Vacuum Hold | 1 | <-6 psig | 85 | -6 psig | |

| Purge | <1 | 6 psig | 100 | 6 | |

| Hold | 20 | 6 psig | 110 | 6 | |

| Vacuum 3 | 12 | -1.0 psig/min | 85 | -6 psig | |

| Vacuum Hold | 1 | <-6 psig | 85 | -6 psig | |

| Purge | <1 | 6 psig | 110 | 6 | |

| Hold | 20 | 6 psig | 110 | 6 | |

| Vacuum 4 | 12 | -1.0 psig/min | 85 | -6 psig | |

| Vacuum Hold | 1 | <-6 psig | 85 | -6 psig | |

| Purge | 36 | 1 psig/min | 122.6 | 17.1 | Gradually increasing the steam pressure to the sterilization settings |

| Sterilize | 60 | 17 psig | 122.6 | 17.1 | Not to exceed 123°C |

| Exhaust | 17 | 0.5 psig | 100 | 0.4 | Gently cooling the cartridge is critical to avoid thermal stress |

| Cool | 50°C |

References

- User Guide – XcellTM ATF Systems Filter Preparation and Autoclave

- Bioprocessing ONLINE/ Refine Technology, LLC

Subscribe to our Newsletter

Stay tuned with Industry updates

| Thank you for Signing Up |